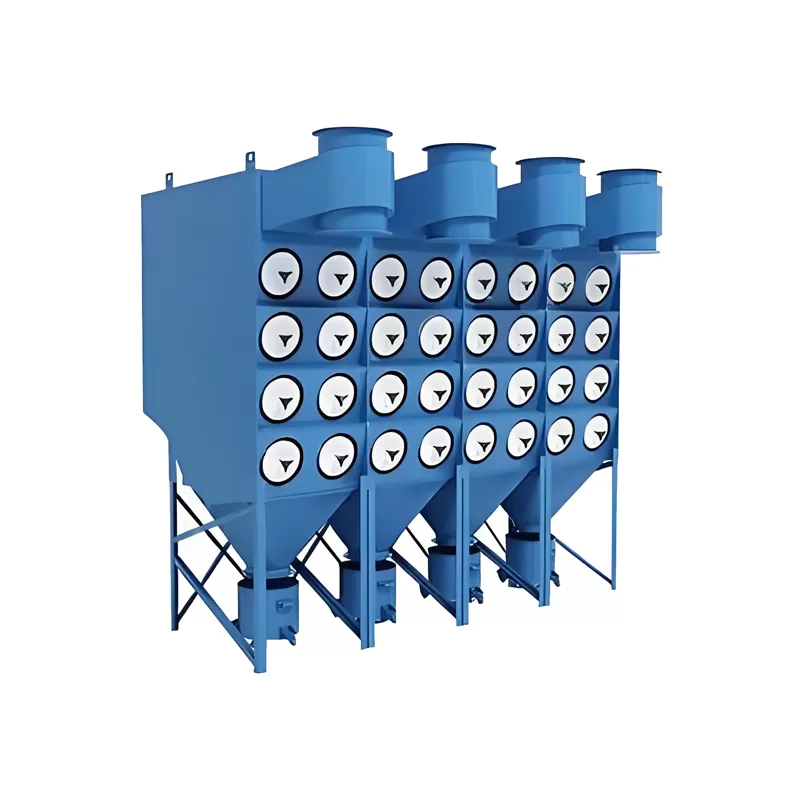

Working principle of Cartridge Dust Collector

The dusty gas generated by industrial cutting, polishing, grinding and other processes is sucked into the box by the fan through the dust suction pipe and enters the filter cartridge for filtration. The smoke dust particles are retained on the outer surface of the filter cartridge. The air purified gas filtered by the filter cartridge is discharged from the air outlet and can be directly discharged indoors for recycling, but can also be discharged outdoors as needed. The entire dust removal and filtration process is a result of the combined effects of gravity, inertia, collision, electrostatic adsorption, screening and so on.

Use industry: Mainly used in welding smoke, cutting smoke, grinding smoke, widely used in the pharmaceutical industry (for example: tablet press, sugar coating pot, mixer, crusher, powder sifter and other process equipment) and casting, ceramics, building materials, loading and unloading, mechanical processing, metallurgy and mining, mining rock drilling, food, flour and other industries for dust removal.

Specification of Cartridge Dust Collector

Cartridge dust collector | model | Dimensions | power | Air volume | Filter method | Cleaning method |

2 barrels | 600*800*1800 | 2.2KW | 2200 | Filter Cartridges | pulse |

4-barrel | 800*800*2000 | 3.0KW | 3000 | Filter Cartridges | pulse |

6-barrel | 1200*1000*2200 | 5.5KW | 6000 | Filter Cartridges | pulse |

9 barrels | 1200*1500*2300 | 7.5KW | 7000 | Filter Cartridges | pulse |