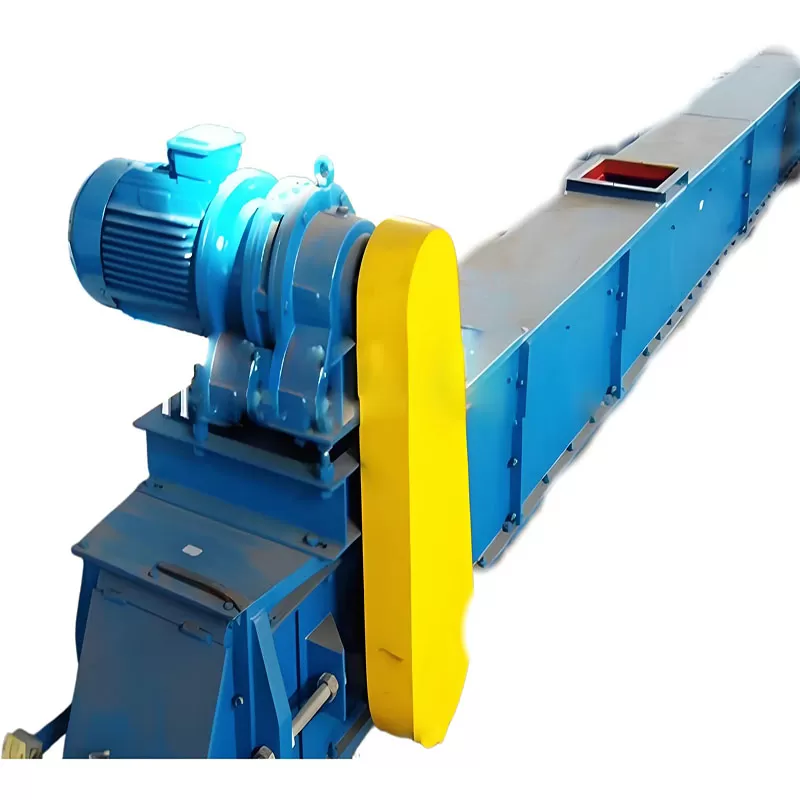

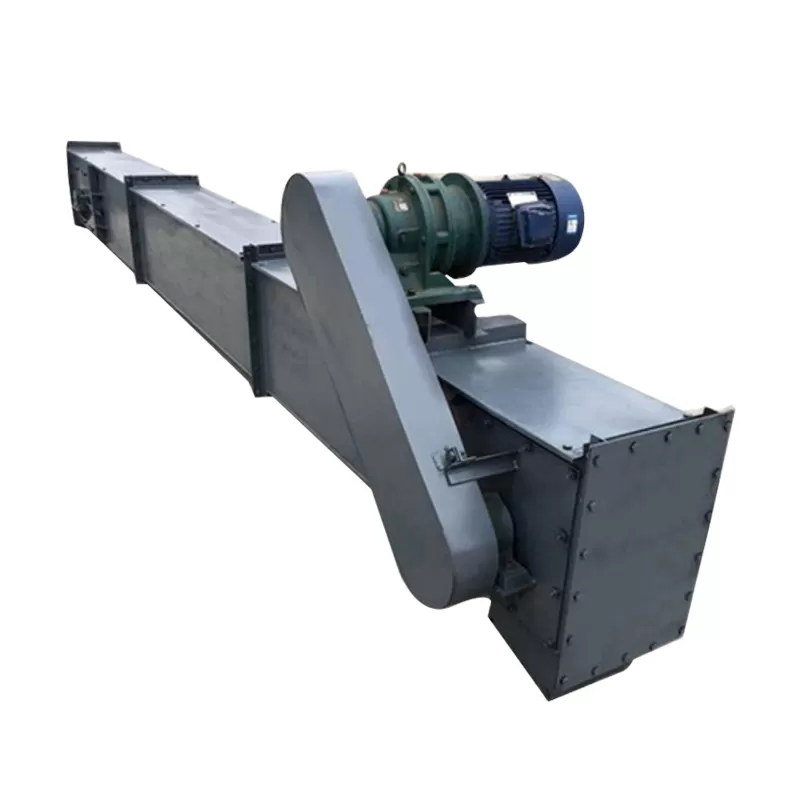

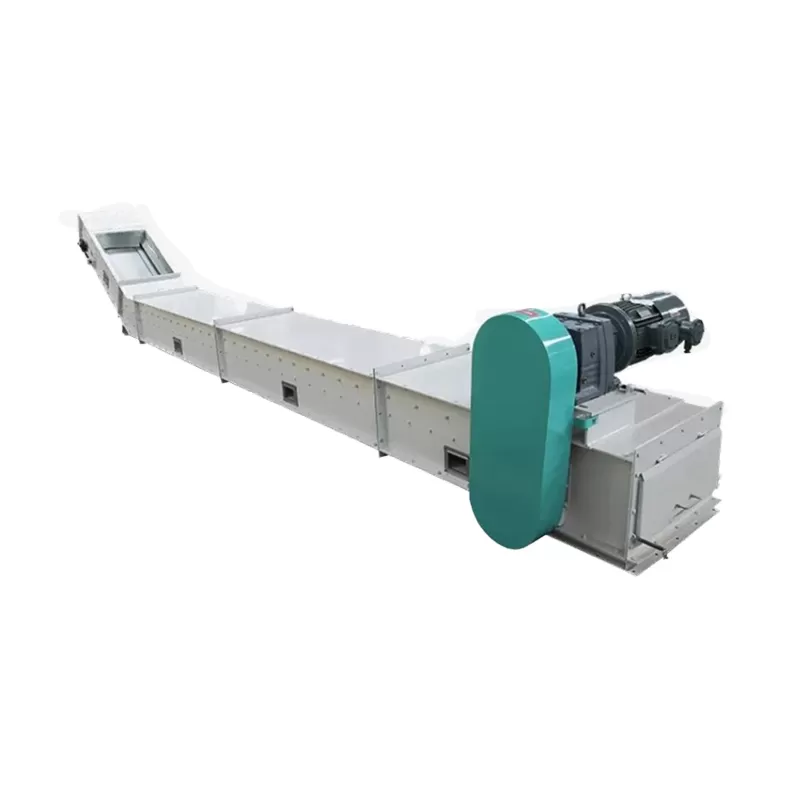

Working principles of FU Chain Conveyor:

FU Chain Conveyor, its advantage derives from its working principle. Because the material has internal friction and lateral pressure, the movement of the conveyor chain increases the internal pressure of the material in the machine tank and the internal friction between the particles. When the internal friction between the material layers is greater than the external friction between the material and the groove wall, the material flows forward along with the transport chain like water. When the ratio of the material layer height to the machine groove width meets certain conditions, Form a stable material flow. The advanced conveying principle, excellent design, and manufacturing process provide a reliable guarantee for the excellent performance of this series of products.

Selection and process layout

The specifications of the FU chain conveyor are listed in the table below. The table lists the range of conveying capacity of each model at different chain speeds. The same conveying capacity can be selected in the table for different models. If a larger model is used, the chain speed is lower and the wear is small, but the equipment investment is higher. If a smaller model is selected, the chain speed is faster and the wear is relatively high. High, but the equipment investment is less provincial.

It should be pointed out that when the actual delivery volume does not reach 65% of the machine's delivery capacity, the conveyor chain is idle due to the thin material layer in the machine tank, which also increases equipment wear. Therefore, it is recommended that the actual delivery volume of the conveyor should not be lower than the minimum value of the delivery capacity in Table 1. After the actual delivery volume is multiplied by 1.2, it should not be higher than the maximum value of the delivery capacity in the table.

Features of FU Chain Conveyor

Large conveying capacity, allowing a large amount of material to be conveyed in a small space, with a conveying capacity of 6 to 600m3/h.

The conveying energy consumption is low, saving 50% electricity compared with screw conveyors.

The sealing performance is good, and the fully sealed casing has little pollution to the environment.

Long service life: the conveyor chain is made of alloy steel through advanced heat treatment, with normal service life of >5 years and the roller life of the chain ≥2-3 years.

Save money. Save electricity and be durable, require less maintenance, reduce consumption and improve efficiency.

Flexible process layout. Can be horizontal or sloped (≤15°).

Specification of FU Chain Conveyor

Model | Optimum conveying capacity (m³/h) | Installation angle | Material humidity |

Chain speed (m/min) |

11m/min | 13.5m/min | 14m/min | 17m/min | 21m/min |

FU150 | 6-10m³/h |

|

|

|

| ≤15° | ≤5% |

FU200 | 12-18m³/h |

|

|

|

| ≤15° | ≤5% |

FU270 | 22-33m³/h | 26-40m³/h |

| 33-50m³/h |

| ≤15° | ≤5% |

FU350 |

|

| 43-64m³/h | 54-80m³/h | 66-98m³/h | ≤15° | ≤5% |

FU410 |

|

| 60-90m³/h | 73-110m³/h | 90-135m³/h | ≤15° | ≤5% |

FU500 |

| 80-120m³/h |

| 105-160m³/h | 140-200m³/h | ≤15° | ≤5% |

FU600 |

| 120-160m³/h |

| 150-220m³/h | 200-290m³/h | ≤15° | ≤5% |