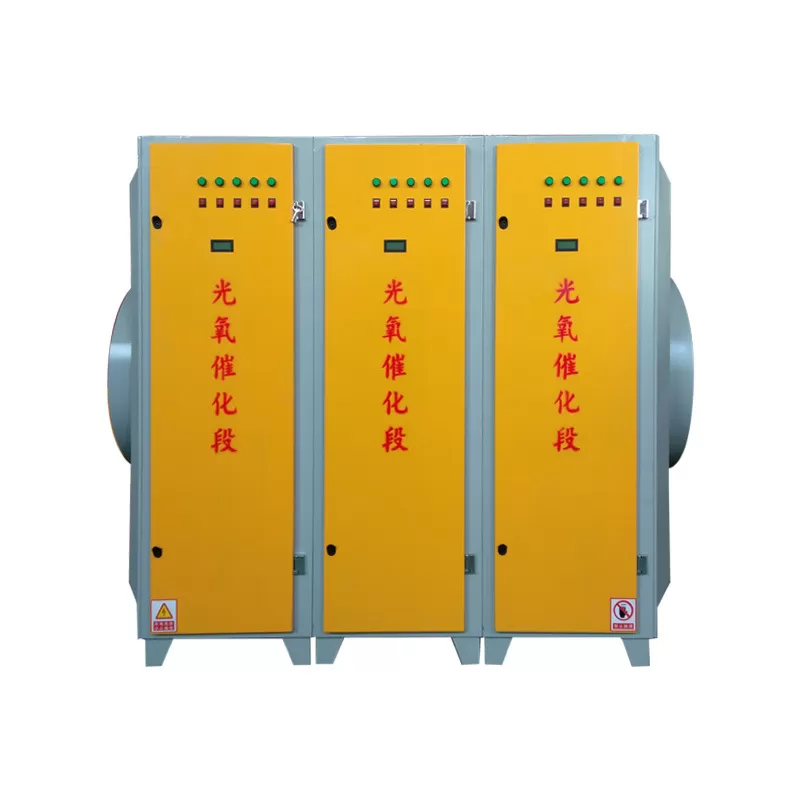

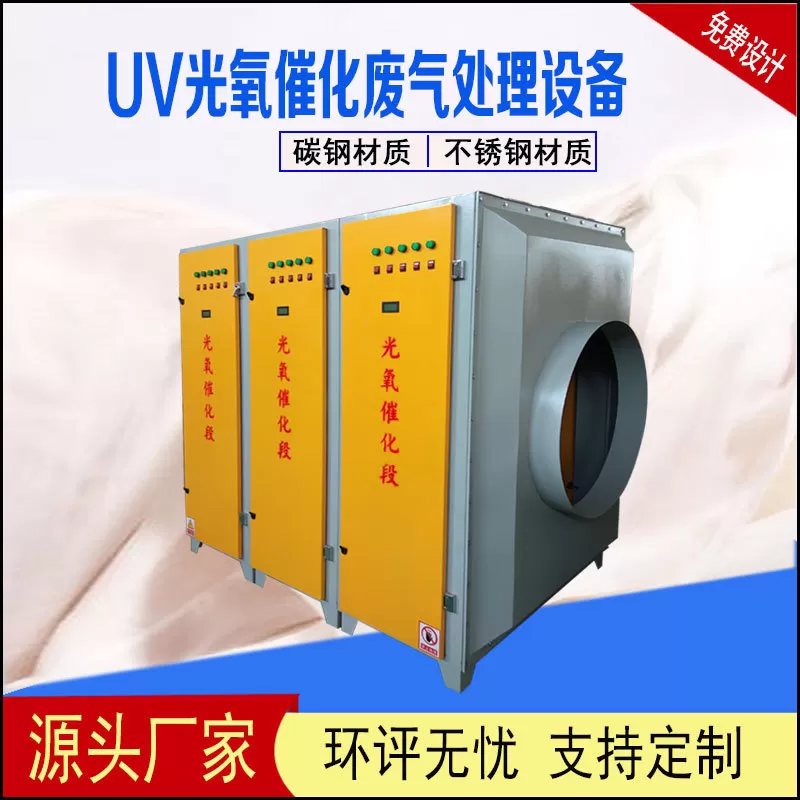

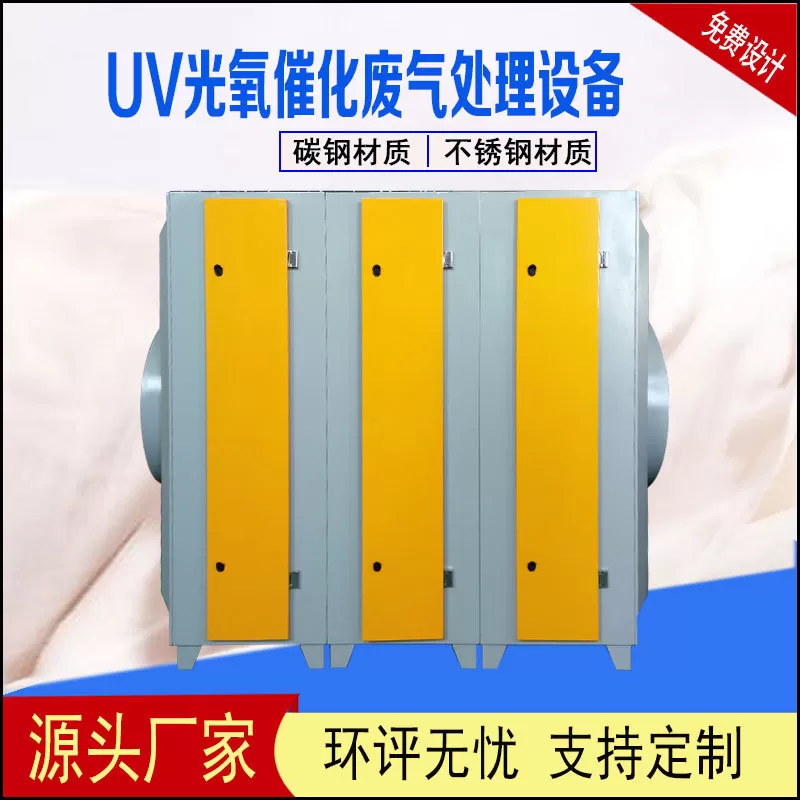

The Structural Composition of a UV Photocatalytic Purifier Generally Includes the Following Parts:

● Ultraviolet generating device: mainly composed of ultraviolet lamps, which can generate ultraviolet rays of a specific wavelength to excite photocatalysts.

● Photocatalyst layer: usually a photocatalyst coated or fixed on a suitable carrier, such as TiO₂, which catalyzes reactions in synergy with ultraviolet rays.

● Air inlet: used to introduce air to be purified.

● Air outlet: discharge the purified air.

●Box: It supports and protects the internal structure and is usually made of corrosion-resistant and high-temperature-resistant materials.

●Filter device: Some may be equipped with a primary filter layer, such as a filter, to remove larger particles and improve the purification effect.

●Electrical control system: power supply, control circuit, etc., used to control the opening and closing of ultraviolet lamps, the working state of photocatalysts, etc.

This cleaner has the following advantages: it can effectively remove odors, volatile organic compounds (VOCs), formaldehyde, benzene, and other harmful gases and pollutants; it has high treatment efficiency and will not produce secondary pollution; the equipment structure is simple, and the operation is stable and reliable.

It is widely used in industrial waste gas treatment, paint room waste gas purification, printing workshop odor treatment, sewage treatment plant odor treatment, and other fields, and plays an important role in improving air quality and protecting the environment. However, to ensure the safety of personnel and equipment, ultraviolet rays must be protected during use.